Ultrasonic Technology in the Packaging Industry

Ultrasonic transducers are transforming the packaging industry. They offer unparalleled efficiency and precision in various processes by using high-frequency sound waves to facilitate a range of tasks.

Home » Packaging

Sealing

Ultrasonic transducers enable seamless sealing of packaging materials without the need for adhesives or heat. By generating localized heat through ultrasonic vibrations, they effectively bond materials together, ensuring airtight and leak-proof packaging.

Cutting

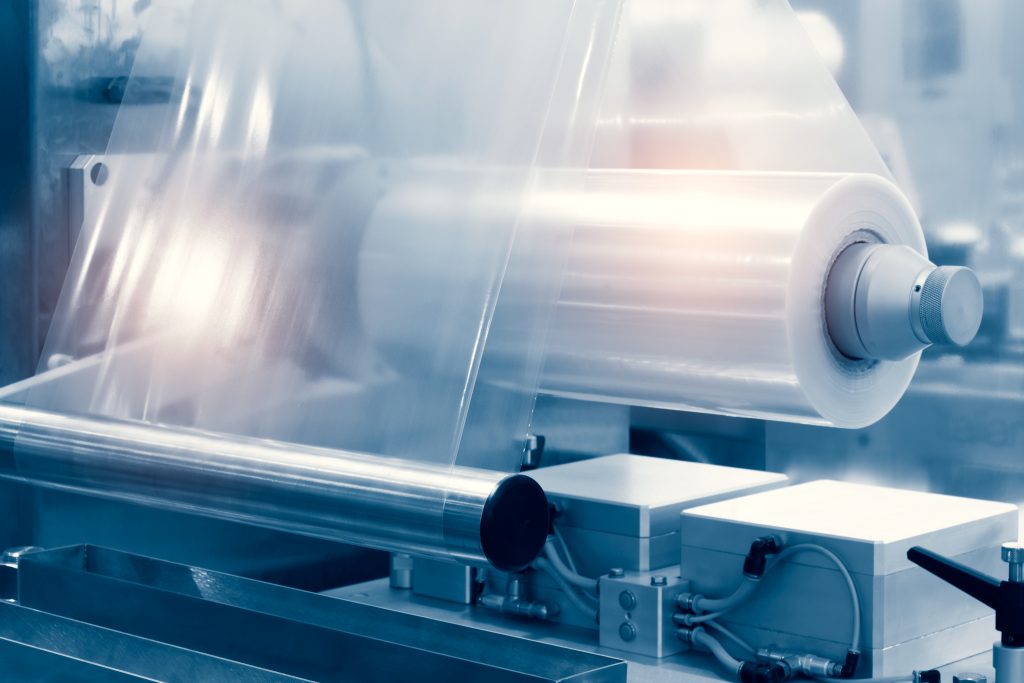

Precision cutting is essential in packaging to create clean edges and uniform shapes. Ultrasonic transducers provide swift and accurate cutting capabilities, even with complex materials like plastics, films, and foils. Their non-contact nature minimizes material distortion and ensures consistent results.

Welding

Joining different components or layers of packaging materials is simplified with ultrasonic welding. Ultrasonic transducers create strong molecular bonds between materials, enhancing the durability and reliability of packaging structures.

Versatility

Ultrasonic transducers are highly versatile and adaptable to diverse packaging needs. They accommodate various materials, thicknesses, and shapes, offering flexibility in design and production processes.

Efficiency

With rapid processing speeds and minimal setup requirements, ultrasonic transducers optimize production workflows and reduce downtime. Their energy-efficient operation contributes to cost savings and sustainability goals within the packaging industry.

Ultrasonic transducers enhance product quality, productivity, and sustainability in the packaging industry. As advancements in technology progress, transducers continue to be indispensable contributors to shaping the future landscape of packaging.